Metal Cleaning

Chemical processes or media blasting are the two primary metal cleaning methods used at Redi-Strip. Incoming metal is pre-cleaned BEFORE performing any other process. Oil, grease, rust, mill scale, paint, coatings, corrosion products, chemicals, deposits, weld smut, heat marks and other surface contaminants are removed to customer specifications. Cleaning may be as simple as degreasing only or more specific. Metal cleaning is the single most important process for successful coating applications.

Metal Pre-Treatment

Metal Pre-treatment refers to processes to physically alter the various subtrates to prepare a foundation to better accept subsequent coatings.

For example:

Zinc Phosphating creates corrosion resistance on Steel in order to provide an excellent base for paint and coatings.

Manganese Phosphating, also known as Parkerizing, imparts superior corrosion resistance and lubricity to friction bearing components such as gears.

Passivation protects stainless steel against oxidation, pitting and premature failure by forming a passive oxide layer on the surface.

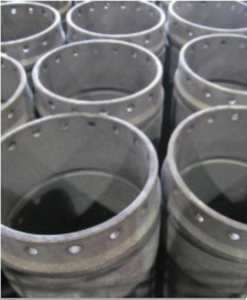

Metal Finishing

Paint or coatings are the most common means of “finishing” to protect steel surfaces.

Paint or coatings are the most common means of “finishing” to protect steel surfaces.

Coatings are chosen to provide corrosion protection from the environment, friction reduction or other specific functions.

Redi-Strip produces ‘paint’ coating systems to specification, including organic, inorganic, inhibitive, zinc-rich, phenolic, epoxy, urethane, vinyl, non-stick PTFE, Xylan, and more. Oiling seals phosphate coatings and provides long-term rust protection for freshly pickled (derusted) steel pipe.