Process Overview

Metal Cleaning, Finishing and Coating is truly an art, due to the many varients. This page is to show you a glimpse of the number of processes our team of experts engage in daily to ensure the best quality service and meticulously finished products!

As you may have learned on our “Service” overview page, Chemical Cleaning is the first step in in the process sequence in order to degrease and/or strip the surface of paint or other coatings.

Typically, chemical cleaning involves immersing products in carefully formulated process solutions. Alternatively, the solutions may also be applied by hand, sprayed, pumped or circulated. The product may also undergo further cleaning if necessary to remove any remaining contaminants, or may simply proceed to the pre-treatment and finishing.

Chemical Immersion

Products undergoing chemical process treatments are immersed in large tanks of chemical solutions. The process solution used depends on product specifications and chemical compatibility of the product. Submerging and soaking allows the product to be completely saturation by the solution in order to thoroughly clean all surfaces including hidden areas that are not accessible with other types of treatment.

Hot Caustic Degreasing and Stripping

The Hot Caustic procedure degreases the metal surface and strips it of paint and coatings. The hot alkali aqueous cleaning solution effectively removes oil & grease, soil, chemicals and ‘strips’ paint and coatings; however, it does not remove rust or mill scale. Hot Caustic can be used with most metal substrates, but not aluminum, zinc castings, pot metal and or incompatible mixed substrates.

Cold Stripper (Degreasing and Stripping)

Cold Stripper is used to clean aluminum, pot metal or mixed metal substrates that are incompatible with Hot Caustic solution. The organic solvents in the cold stripper dissolve a wide range of organic compounds, making it an effective degreaser and paint stripper.

Acid Pickle (Rust Removal)

Pickling is used to de-rust or remove rust, mill scale and oxides from precleaned metal. The pickle is an aqueous solution of muriatic acid containing chemical inhibitors that protect the substrate against aggressive acid attack. Suitable substrates include ferrous metals, carbon steel, cast iron, copper, brass alloys. Immediately upon removal from the pickle, products are neutralized and rinsed clean. After pickling, products can be protected from rusting by phosphating, passivation or oiling.

Solvent (Degreasing)

Solvent cleaning is sometimes used for products requiring high levels of cleanliness, as in Cleaning for Oxygen Service, or for products with mixed substrates. The solvent is chosen for its ability to remove soluble oil, grease and organic contaminants, while not damaging the substrate.

Water Rinse

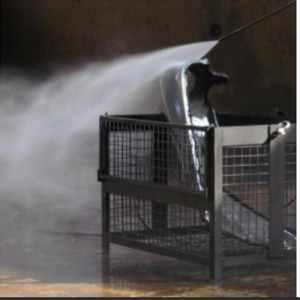

Immediately upon removal from a process solution, parts are rinsed clean of chemicals. Redi-Strip’s experienced rinsers pay special attention to tight seams, blind cavities and small crevices to flush out trapped chemicals.

Redi-Strip uses fresh, potable, filtered, high pressure, hot or cold water for rinsing. Deionized Water (DIW) is available as an option for the final rinse to achieve more stringent cleanliness, as required with more exacting procedures such as Passivation of Stainless Steel or Cleaning for Oxygen Service.

Drying

The drying of parts and products may or may not required after rinsing between chemical treatments but are thoroughly dried after the final water rinse.

Natural air drying, forced air drying, oil-free forced air drying or nitrogen drying are some of the drying options at Redi-Strip.

The drying method selected depends on various factors, including subsequent processes, whether flash rust will be a problem, the substrate material and customer specifications.

After the appropriate method of Chemical Cleaning has been achieved, the next step in the process sequence is Pre-treatment.